ZoneSafe Collision Avoidance

Advanced RFID proximity detection technology designed to prevent collisions between vehicles, machinery, and personnel in high-risk mining environments—where visibility is limited and consequences are severe.

Overview

ZoneSafe is a proven RFID (Radio Frequency Identification) proximity warning system purpose-built to eliminate blind spots and reduce struck-by, pinning, and crushing incidents in mining and quarry operations. Widely deployed across surface and underground sites, ZoneSafe creates an adjustable, invisible safety zone around heavy machinery such as haul trucks, excavators, loaders, drills, and support vehicles. Unlike camera or radar-based systems, ZoneSafe’s RFID technology works reliably in dust, fog, darkness, and obstructed conditions—providing real-time, bidirectional alerts to both operators and pedestrians before an incident occurs.

Advanced Features

Engineered with cutting-edge technology to provide unmatched visibility and safety

RFID Proximity Detection

Reliable non-line-of-sight RFID technology detects tagged personnel, vehicles, and assets—even in dust, fog, darkness, or obstructed environments.

360° Safety Zone Coverage :

Creates an adjustable, invisible detection zone around machinery, providing full blind-spot coverage from all directions.

Bidirectional Alerts:

Simultaneous warnings for operators (audible & visual in-cab alerts) and pedestrians (vibration and optional audible alerts via wearable tags).

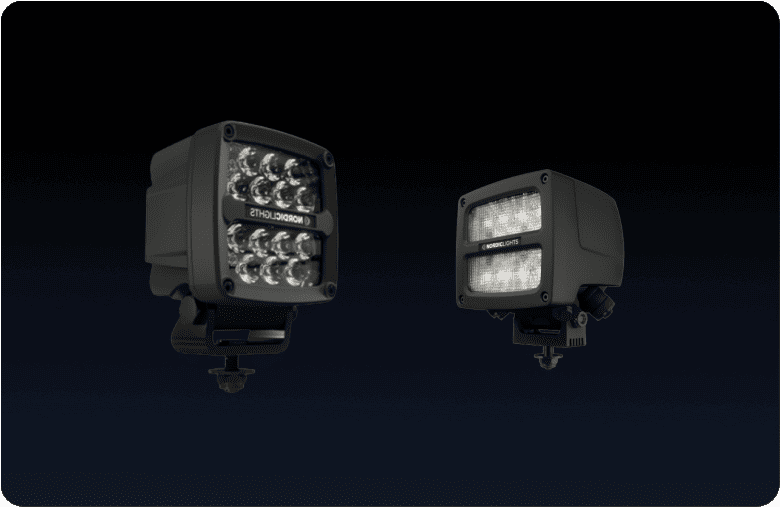

Mining-Grade Rugged Design:

Engineered for harsh mining conditions with vibration resistance, IP-rated dust/water protection, and stable performance in extreme temperatures.

Flexible System Configuration:

Supports vehicle-mounted systems, wearable personnel tags, fixed-zone tags, and site-wide alert devices such as beacons and signs.

No False Alarms:

Unaffected by weather, dust clouds, poor lighting, or environmental clutter—delivering consistent, accurate detection.

System Integration Ready:

Integrates with alarms, cameras, telematics, traffic lights, and access control systems for a unified safety solution.

Data & Event Logging:

Optional logging of zone breaches and near-miss events to support safety audits, analysis, and continuous improvement.

Measurable Benefits

Proven results that impact your bottom line and keep your team safe

Proactive alerts prevent near-misses from escalating into accidents.

Protects ground workers in congested loading zones, haul roads, and intersections.

Eliminates blind spots on large mobile plant and articulated equipment.

Maintains accuracy where cameras, mirrors, or radar may fail.

Supports mining safety programs and proximity detection guidelines (including MSHA-aligned practices).

Fewer accidents mean reduced equipment damage, injuries, and operational disruption.